3D printing with the help of the best large format 3D Printer is regularly more finding its place. The technology is utilized in applications as varied as split bearings, automotive components, medical implants plus footwear. However, what these applications have in widespread is that the parts being generated are all of a comparatively small size. Visit our official website to buy now!

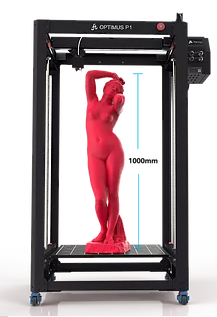

Large format 3d printing has evolved slowly in recent times as a cost effective, flexible solution for producing large components of industrial grade products and equipment. Majority of 3d printers still available today are mainly to manufacture small parts, therefore, the need for efficient large scale 3D printing technologies is emerging rapidly to revolutionize several sectors with rapid manufacture technological solutions. Large format 3d printer machines are used in several applications like split bearings, manufacturing automobile parts, medical devices and footwear. Manufacturing large turbines, hefty aircraft wings, larger tools may be cumbersome and time consuming. With large-scale 3d printing they can be easily manufactured with a single print run making it lightweight and enhancing the overall performance of the process. Thus, although this technology is still a niche one, but it has ample potential for solving many industrial challenges faced on daily basis while producing larger manufactured goods. Top 3 best large format 3D printer of 2020. Large scale 3D printers are heavy on the pocket; therefore some through research needs to be conducted before you make your choice. Below are listed top 3 printers of this year for your convenience:

- MODIX BIG60: The best value large format printer available with high build volume, heated bed with silicon heater, automated bed leveling and a filament sensor is here to help small business to run efficiently.

- RAISED PRO2 PLUS: The best one in the market with high build volume, dual extrusion and Wi-Fi connectivity. Although, a bit pricey but it is the best choice if quality is the foremost thing for you.

- CREALITY CR-10S: It is powerful, reliable yet affordable with a high build volume and top features making it the most popular budget friendly choice of the year.